Printers are of daily use, and without ink they’re useless. But buying the ink frequently will cost you a lot of money. It’s better to spend money once on getting high-quality ink that can be compatible with the cartridge and the printer as well. To make the printer and the ink cartridge last longer and save money, it’s advisable to check the ink quality.

But here the query arises, what is printer ink made of?

The ink was primarily made of many different natural substances. Now the main component is carbon black. Other components are organic or inorganic. Few are the following:

- Pigments

- Resins

- Dispersants

- Humectants

- Wetting Agents

To know about its composition in detail, lets us go into the detail further:

History of Ink

About 4500 years ago, man-made ink was first made from natural substances such as natural gums, suspensions, tannin from tree barks, etc.

Printing Inks were first made by the Chinese around 2500 BCE. Its components were plant matter, gums, glue, soot, and colored earth.

With time, many changes were brought and components were added, which gave it high quality, and now it can be used in printers. This is now called printing ink. Another category of ink is writing ink. But we’ll discuss the composition of the printer’s ink.

What is the Ink made of?

The main component of the ink is carbon black. Following are the other components used in the preparation of the printer’s ink.

Pigments

Colouring of ink!

The vital component of ink pigments. They are used in ink in highly ground form. Here are the functions that pigments perform in the composition of ink:

- Provide color to the ink

- Add gloss and shine to the ink

- Abrasiveness to surface

- Also add the resistance of chemicals, water, etc.

Pigments aren’t used alone. To increase their efficiency, two components are used:

- Opacifiers

They cover the printing surface making the ink transparent because they are white.

- Extenders

They decrease the intensity of pigments because they are clear.

Resins

Binding ink to the surface!

Multiple resins are used in an ink such as acrylics, alkyds, formaldehyde and ketones, etc. Resins have the following functions and benefits:

- Make a distinct film and Bind ink to the surface

- Enhance the mechanical and rheology properties

- Make surfaces glossy, shiny

- Make surfaces water, heat, and chemical resistant

If interest, also read, what is toner made of!

Dispersants

Easy flow of ink!

To make the flow of ink easy and to keep it a semi-liquid material, dispersants are used. Following are the other benefits of dispersants:

- Mechanical energy or friction is reduced

- Easily transfer ink to the surface

- Stabilize the pigment particles

- Also, prevent the fine pigments from settling

- Settle the intensity according to color

Dispersants are surfactants and polymers. It functions in a way to get dissolved in a solvent and a coating is formed that is different from the composition of different colors.

Other Secondary Components

To give the ink a better quality and improve functioning other components are also used as well.

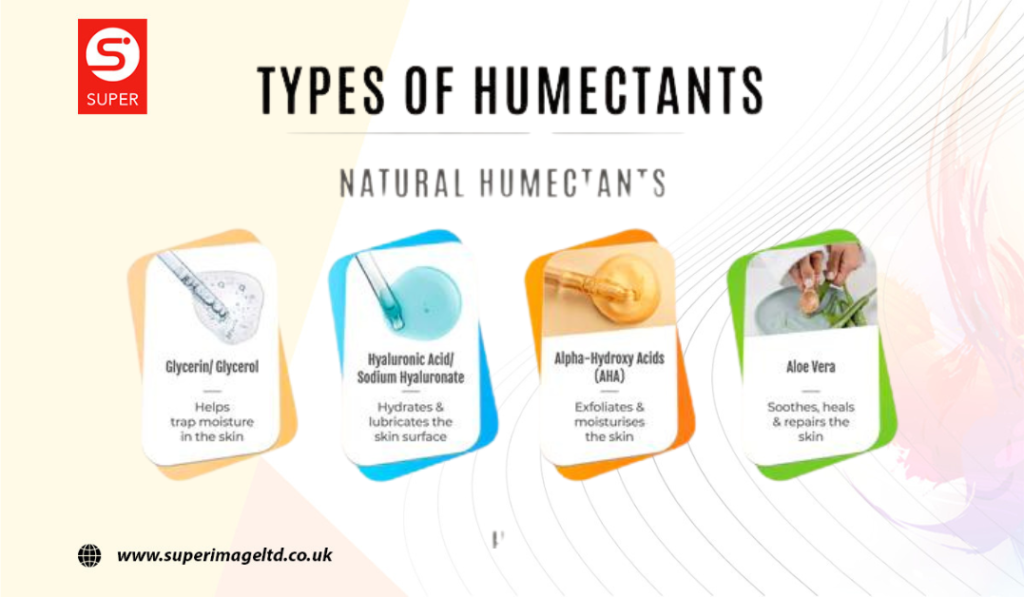

- Humectants

It helps to increase the life of ink by keeping it fresh and well printable for a long time.

- Drying agents

To dry the ink and also to bind it to the surface without wetting the surface, drying agents are used.

- Wetting agents

Surface properties like shining, gloss, friction, all are controlled by wetting agents.

- Surfactants

They also play a major role as they also optimize the printability of the ink

- Lubricants

To reduce resistance and provide rub, they are used.

- Biocides

These prevent the growth of bacteria and fungi. Bacteriostats are also used along with that to help prevent the attack of anything.

- Defoamers

To increase efficiency and make bubbles, defoamers are used. They also regulate the formation of foam in ink.

- Amine Derivatives

Maintenance of pH is also important for ink. This is done by amine derivatives. They modify the pH as per requirement.

Ingredients in Printers Ink Colors

The base ingredient of printer’s ink is oil – be it soybean oil, linseed oil, petroleum distillate.

Following are the base components of black ink and the colored Ink

- Black Ink

It is made of carbon black and varnish. Other components or chemicals are also used to change the opacity of the ink. To give it a greyer color, a white component of titanium dioxide can also be used.

It will enhance and make a good blackish grey color. Titanium dioxide can give shining, depth, or water-resistant properties.

- Coloured Ink

This ink is called organic ink as the main components used are organic. These are widely used inks as colored inks. It is made of salts, dyes, or compounds such as:

- Yellow lake

- Peacock blue

- Diarylide Orange

- Phthalocyanine green

Inorganic Inks are made up of lead chromate, sulfate, and molybdate. They pursue the following colors:

- Cadmium Yellow

- Chrome green

- Molybdate orange

- Prussian blue etc.

Conclusion

Hence, you have learned the components of the ink. In the early time, it was made of materials of daily use and basic things, including fruits and vegetables. But now, it cannot be done in this way. High technology and manufacturing procedures are used to prepare it with many chemicals and pigments.

This is why it is getting expensive. The high-quality ink is manufactured nowadays. That’s why more demand has increased the supply. Ultimately increasing the revenue for the marketers.

FAQ‘s

Printer ink is mainly composed of water, pigments, and dyes, with pigments providing color and dyes enhancing saturation.

Many modern inks are water-based, making them less harmful to the environment compared to older solvent-based formulations.

The quality depends on factors such as color accuracy, fade resistance, and compatibility with the printer model.

While it’s possible, using third-party ink may void your printer warranty, and the quality may vary.

Dye-based inks are vibrant and better for photo printing, while pigment-based inks offer durability and are suitable for text documents.